Keeping the world moving

Published Sept. 15, 2022

Susana Inda is a natural problem solver, which is a required skill for ensuring that Boeing is receiving the highest quality products and materials from suppliers.

As part of Boeing Commercial Airplanes (BCA), Susana works as a supplier quality specialist in Mexicali, Baja California, partnering with suppliers throughout Mexico — Boeing’s largest region of Latin American suppliers — as well as Southern California.

“My responsibility is to make sure suppliers provide quality materials with zero defects,” Susana said. “If any problems arise, I help identify the issue and work through the quality management system with my business partners to find a solution.”

Receiving high-quality materials on time allows our company to build products and provide services that help keep the world moving. Whether she’s dealing with non-conforming parts or not receiving materials on schedule, Susana draws on her supplier quality expertise to help resolve and limit manufacturing disruptions.

Susana cites having an understanding of Mexican culture and the ability to speak multiple languages, including Spanish, in helping her work productively with her global partners.

“Many of the suppliers I partner with speak English as a second language and some of the technical definitions are difficult to understand in translation,” Susana said. “Speaking in Spanish helps when we encounter communication barriers.”

Her years of experience recently led to Susana becoming a lead trainer for the Boeing Production System (BPS) training team. BPS is a set of principles, best practices and standards designed to drive companywide stability and continuous improvement. The training has been crucial to creating a safer environment focused on delivering results with first-time quality. As a trainer, Susana teaches problem-solving methods to use while working with suppliers.

“I’ve taught this series of courses to representatives throughout the company,” Susana said. “The training shows attendees how to find the root cause of problems through a hands-on approach, allowing them to improve interactions with suppliers, identify problems before they happen, and strengthen our overall supply chain.”

Recently, Susana coupled her supplier quality expertise with her position as chair of the Boeing Familia Business Resource Group - Latino America chapter. In collaboration with the BCA Southern California Supplier Quality team, the chapter hosted an event about key inspection processes and best practices to better execute inspection reports and meet aerospace standards.

“I enjoy sharing my experiences and helping teams improve each day,” she said. “We can learn from each other by sharing best practices and working together. Problems and challenges can be overcome with the right methodology.”

-

Our Environment

Our EnvironmentWe're committed to environmental stewardship — an important pillar of our broader sustainability strategy to help make the world better for future generations.

-

Career Areas

Career AreasJoin our team of innovators and dreamers, engineers and designers, cybersecurity experts and technologists. This is where you'll help build tomorrow today.

-

Community Engagement

Community EngagementSee how everyone here is an involved and engaged member of our communities.

-

Innovation is in our DNA

Innovation is in our DNASee how we innovate and operate to make the world better.

-

Boeing Career SkillBridge Program

Boeing Career SkillBridge ProgramApply for opportunities in engineering, product support, IT, manufacturing and other areas.

-

Two Ways To Stay Connected

Two Ways To Stay ConnectedJoin our Global Talent Network and sign up for Job Alerts to learn about additional opportunities.

-

Benefits

BenefitsOur Total Rewards program includes best-in-class benefits designed to meet your needs at every stage in life.

-

Working Here

Working HereWe're a company of inquisitive, talented people. Find out what's important to us and what inspires us to do amazing things together.

-

Inside Boeing

Inside BoeingSee what it means to be part of #TeamBoeing. Explore stories and learn how our people grow their careers while shaping the future of aerospace.

-

Our Locations

Our LocationsOur global presence includes employees and operations in more than 65 countries. Explore some of our locations.

-

Frequently Asked Questions

Frequently Asked QuestionsSee some of the most commonly asked questions about starting a career with Boeing.

-

Search for Events in Your Area

Search for Events in Your AreaOur hiring events are a great way to learn about our innovations and culture.

-

Military and Veterans

Military and VeteransJoin thousands of veterans who chose Boeing for their next mission.

-

Internships

InternshipsGain hands-on experience and work alongside a team of industry leaders as you help build the future.

-

-

-

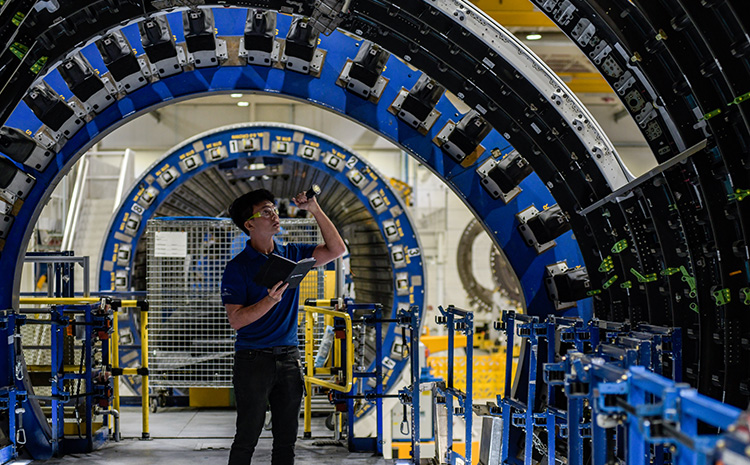

Manufacturing and Quality Roles in Seattle

Manufacturing and Quality Roles in SeattleBuild advanced aerospace products while growing your skills and earning best-in-class benefits.

-

Shaping Tomorrow's Innovations

Shaping Tomorrow's InnovationsOklahoma City is where you’ll shape tomorrow’s innovations.

-

Denise and Kay, Materials Engineers

Denise and Kay, Materials EngineersMother and daughter duo Denise and Kay push aerospace innovation forward every day.

-

Tresha, Chief Engineer

Tresha, Chief EngineerFascinated by kit airplanes as a child, Tresha is now chief engineer for the world’s most efficient twin-engine jet.

-

Kariza, Composite Research Engineer

Kariza, Composite Research EngineerWith a curiosity inspired by school projects, Kariza now helps develop sustainable aerospace technology.

-

Boeing's Employee Referral Program

Boeing's Employee Referral ProgramLearn how Boeing employees can earn a bonus by referring external hires.

-

Return Flight Program

Return Flight ProgramBoeing’s Return Flight Program provides people with a pathway to return to their careers after an extended break.

-

‘Understand the challenges to see the opportunities’

‘Understand the challenges to see the opportunities’Christina Upah believes problem-solving starts with a great team.

-

‘I was encouraged to get out of my comfort zone’

‘I was encouraged to get out of my comfort zone’How a conversation at a career fair led business operations leader, Jennifer, on an unexpected career path.

-

‘We’re solving the world’s hardest problems’

‘We’re solving the world’s hardest problems’From intern to leader, east to west and in between, Laura shares how business and technology merge

-

'People are here to learn and grow’

'People are here to learn and grow’A lifelong Boeing employee, Rodney credits his varied career to managers’ support and his own curiosity.

-

‘Dyslexia doesn’t limit me; it’s an asset’

‘Dyslexia doesn’t limit me; it’s an asset’A teammate’s skill for seeing the bigger picture helps her lead transformation at work and in her personal life.

-

An engineer's career takes flight

An engineer's career takes flight'My team and I are using advanced tools and technologies to help chart Boeing’s future.'

-

'I leaped into the unknown'

'I leaped into the unknown'Suellen achieved her dream to become a Boeing engineer. Now she’s mentoring our future leaders.

-

Boeing Technical Apprenticeship Program

Boeing Technical Apprenticeship ProgramEarn as you learn technical skills and receive credentials that can set you up for success.

-

'Speaking up can save lives'

'Speaking up can save lives'Read how Dr. Catherine Sinclair, a software engineer with Boeing Defence Australia, increases awareness of domestic abuse and supports gender equity.

-

Giving Back to the Country She Loves

Giving Back to the Country She LovesRomina Cutescu, a systems engineer, works on programs that are critical to homeland security.

-

“You can have five careers at Boeing.”

“You can have five careers at Boeing.”Since interning, Emily completed rotations in four business units and worked on the cargo air vehicle program. Today, she is a flight test engineer for the T-7A program.

-

Thurgood Marshall College Fund

Thurgood Marshall College FundBoeing's partnership with Thurgood Marshall College Fund is an initiative supporting HBCUs through campus recruitment, career immersion, scholarships, and more.

-

Continuous Improvement: Meet Enrica, Industrial Engineer

Continuous Improvement: Meet Enrica, Industrial EngineerFind out how Enrica is advancing her career at prestigious universities around the world with tuition assistance from Boeing.

-

Leading by Example: Meet Tony, Vice President of Army Systems

Leading by Example: Meet Tony, Vice President of Army SystemsAnthony 'Tony' Crutchfield, Boeing vice president and retired lieutenant general, shares decades of leadership experience with students and early career professionals from underrepresented communities.

-

Angelie Vincent, Product Development Engineer, Recounts Her Journey With Autism

Angelie Vincent, Product Development Engineer, Recounts Her Journey With AutismAngelie has been with Boeing for 12 years and was diagnosed with autism in April 2019. Through her story, she inspires others to overcome adversity.

-

Boeing in South Korea

Boeing in South KoreaWe’re proud of our 75-year partnership with South Korea. Join us and help revolutionize aerospace development from the heart of Seoul.

-

Boeing in India

Boeing in IndiaThe most exciting advances in aerospace are being developed today in India. Join us and build a career at the center of our industry’s future.

-

Boeing in the UK

Boeing in the UKAcross 30 key locations in the UK, we employ more than 3,000 highly skilled teammates. And, after 80 years of success, we keep growing.

-

Boeing in Washington, D.C.

Boeing in Washington, D.C.Whether you're a software engineer, systems engineer, or cyber analyst, help us solve tough challenges and contribute to the security of the nation.

-

Boeing in Missouri

Boeing in MissouriJoin us and contribute to next-generation aircraft, training, and defense products and capabilities.

-

Boeing in Poland

Boeing in PolandWe develop technologies that will shape the future of flight and we need your curiosity and unique perspective to help keep us innovating.

-

Boeing in Oklahoma

Boeing in OklahomaLearn how we continue to create opportunities for bright minds and see what makes this a great place to build a career.

-

Boeing in Alabama

Boeing in AlabamaAs the largest aerospace company in the state, we play a vital role in the U.S. space and defense programs.

-

Boeing in California

Boeing in CaliforniaAs we transform aerospace, your skills will take center stage. Join us and help connect, protect and explore our world and beyond.

-

Boeing in Brazil

Boeing in BrazilFor more than 90 years, we’ve partnered with Brazil and today you can join a team filled with creative minds who are building what’s next.

-

Boeing in Texas

Boeing in TexasExplore what makes Boeing in Texas a great place to work.

-

Boeing in Japan

Boeing in JapanFor more than 50 years, we’ve worked closely with Japan to help create the future of aerospace and bring new expertise to our future-focused products.

-

Boeing in Arizona

Boeing in ArizonaKnown for producing the Apache and Little Bird aircraft, we’re also home to centers of excellence in software, composites, wiring and fabrication.

-

Boeing in South Carolina

Boeing in South CarolinaAcross our manufacturing plants, research and technology center, engineering center and propulsion sites, we’re developing new advances in flight.

-

Boeing in Washington State

Boeing in Washington StateAt the center of aviation since 1916, many of our most innovative products are designed and built here.

-

Meet Nathan: Phantom Works Operations Analyst

Meet Nathan: Phantom Works Operations AnalystNathan helps our defence customers make decisions using the power of modelling and simulation.

-

A Mother-Daughter Duo Bond Over Invention

A Mother-Daughter Duo Bond Over InventionMeet Kay and Denise, inventors of an adhesive removal tool and an inspiration to other innovators across our company.

-

Accessibility Accommodations

Accessibility AccommodationsIf you need a reasonable accommodation for any part of the employment process, please contact us.

-

From mechanic to manager

From mechanic to managerRead how our leadership training helped Jacob hone his management skills and grow his career.

-

It’s No Ordinary 9 to 5 For Manufacturing Engineer Lee

It’s No Ordinary 9 to 5 For Manufacturing Engineer LeeMeet Lee, a manufacturing engineer in Boeing’s Melbourne factory who has worked on commercial and defense aircraft, including the first Australian-made autonomous military aircraft, known as the MQ28A Ghost Bat.

-

We never stop growing

We never stop growingWhether you’re looking to expand your knowledge or grow as a leader, our development programs are designed to help you succeed.

-

'What are your qualifications?'

'What are your qualifications?'Meet Danielle and Ankita, two teammates who are breaking biases with the help of allies.

-

Cyber Security Guard: Meet Anna Guthrie, Product Security Engineer

Cyber Security Guard: Meet Anna Guthrie, Product Security EngineerProduct security engineer Anna Guthrie builds resilient technologies to protect against cyberattacks. In this interview, she offers a glimpse into a day in her life with our growing cybersecurity team.

-

No barriers to entry

No barriers to entryThree teammates champion a new approach to helping overcome the “mid-career crisis” and increasing diversity at all levels.

-

Unlock the secret to conquering fear

Unlock the secret to conquering fearEngineering manager Aslihan Karlidag uses Boeing’s digital learning opportunities to keep her fears at bay

-

“There’s no better place to explore new roles and opportunities than Boeing.”

“There’s no better place to explore new roles and opportunities than Boeing.”Chad, a Senior Software Manager, knows that growth happens outside the comfort zone.

-

‘When you feel like the professor, it’s time to be the student again’

‘When you feel like the professor, it’s time to be the student again’Vice president Tresha Lacaux landed her dream internship at Boeing. Today, she’s landed her dream role

-

-

'I feel a part of the Boeing family'

'I feel a part of the Boeing family'Discover how our Neurodiversity at Work program helped Thomas launch his software engineering career.

-

‘I’m inspired by the belief that we can always improve’

‘I’m inspired by the belief that we can always improve’Meet Dr. Rongsheng “Ken” Li, a Principal Technical Fellow who has been awarded for his work in aerospace guidance, navigation and control systems.

-

Meet Suba, a Space Launch Systems Leader who Broke Barriers

Meet Suba, a Space Launch Systems Leader who Broke BarriersDiscover how Suba Iyer turned her fascination with how things work into an engineering career.

-

From Interns to Innovators: Systems Engineers Blaze Paths to Success

From Interns to Innovators: Systems Engineers Blaze Paths to SuccessMeet two systems engineers who are contributing to the next era of spaceflight.

-

Meet Sanh, 777X Design Engineer

Meet Sanh, 777X Design EngineerRead how Sanh Ha, an engineer who is deaf, applied innovative thinking to safely overcome obstacles during a test flight.

-

'We are finding ways to inspire more people around us'

'We are finding ways to inspire more people around us'Meet Nic, a leader in the UK who is advancing equity and entrepreneurial innovation to solve aerospace challenges.

-

From Making Soap to Making a Difference: Meet Oscar Johnson

From Making Soap to Making a Difference: Meet Oscar JohnsonA lifelong interest in chemistry sparked this engineer to desegregate lunch counters in 1960 and unveil cutting-edge technology in Boeing laboratories 50 years later.

-

'There's room for all types of leaders'

'There's room for all types of leaders'Meet Teresa, a product engineer and inventor with multiple patents.

-

Meet Bo, E-7A Wedgetail Systems Engineer

Meet Bo, E-7A Wedgetail Systems EngineerBo designs and develops software and hardware that supports the Wedgetail's missions. Watch the video to learn how his work has an immediate impact.

-

Recruitment Fraud Alert

Recruitment Fraud AlertBe aware of fraudulent job offers purporting to be from The Boeing Company and/or its affiliates. Learn what to look for.

-

From soccer pro to Boeing engineer and leader

From soccer pro to Boeing engineer and leaderAs a material and process engineer at Boeing South Carolina, Nelson earned his bachelor's, master's and doctoral degrees in engineering. See how leadership support and a drive for innovation drove his success.

-

Easing the Transition of U.S. Service Members

Easing the Transition of U.S. Service MembersLearn how our partnership with SkillBridge is supporting veteran teammates in discovering their next mission.

-

-

Meet Jacqueline Lam, Global Sustainability Leader

Meet Jacqueline Lam, Global Sustainability LeaderAn inclusive approach is helping Jacqueline drive sustainable aviation in Southeast Asia.

-

Clocking In: How 7 Hours a Week Changed Jesus’ Life

Clocking In: How 7 Hours a Week Changed Jesus’ LifeMeet Jesus Sanchez, a power machine operator in Auburn, Wash. See how Jesus used our tuition assistance program to obtain an associate degree in business.

-

Three Keys to Mission Success

Three Keys to Mission SuccessAlex Campos, a Boeing Missile Defense contracts administrator and U.S. Navy reservist, shares his advice for staying on mission.

-

Building a Family On Their Terms

Building a Family On Their TermsRead how Kristin Innes and her partner Bonnie are growing their family with help from Boeing's fertility benefits.

-

Not Your Ordinary 9 to 5

Not Your Ordinary 9 to 5Meet Jimmy, an Air Force veteran and aviation safety coordinator that helps teams operating the F/A-18F Super Hornet and EA-18G Growler get home safely.

-

‘If you do right, right will follow you’

‘If you do right, right will follow you’Engineers Debra and Stacia discuss the importance of community connection and making an impact through even small actions.

-

Meet KJ

Meet KJFrom the Rosebud Reservation in South Dakota to leading attack helicopter programs in Mesa, AZ., Kathleen “KJ” Jolivette inspires STEM interest among Native American students.

-

'It's hard to describe the thrill of it'

'It's hard to describe the thrill of it'Meet Ty'Quish, a mechanical engineer who has helped design and build the next-generation assault helicopter.

-

An Engineer's Creative Edge Helps Customers Chart Their Course

An Engineer's Creative Edge Helps Customers Chart Their CourseA a modeling and simulation engineer for Boeing Ground-based Midcourse Defense, or GMD, Kyle mostly deals in a world that’s conceptual, using a modeling system to simulate and predict how a customer request will perform in a real-world scenario.

-

It's a learner's paradise: Meet Rakesh Nanda

It's a learner's paradise: Meet Rakesh NandaDiscover how Rakesh and the design engineering team at the 787 Interiors Responsibility Center in India innovate and grow.

-

The Best Call That I've Made

The Best Call That I've MadeFaced with caring for two sick family members, Sandra Lankford leaned on Boeing's caregiver benefits for support. Watch Sandra's story.

-

Automation is the Future

Automation is the FutureRead how Sarah Wauahdooah, a manufacturing research and development engineer, applies her robotics expertise on the V-22 Osprey program.

-

Meet Satyaki, Helicopter Engineer

Meet Satyaki, Helicopter EngineerSatyaki helps to keep the Australian Army’s CH-47 Chinook helicopters flying around the clock.

-

‘I gained a family of leaders’

‘I gained a family of leaders’Stephanie Yount, engineer and recent Leadership Next graduate, discovers she’s most comfortable when she’s completely uncomfortable.

-

'You can have 20 careers at Boeing'

'You can have 20 careers at Boeing'Meet Boeing finance leader Terrence Chance, and discover the breadth of the experience that's shaped his career.

-

UK Equal Opportunity Statement

UK Equal Opportunity StatementWe are an equal opportunity employer.

-

Non US EOE Statement

Non US EOE StatementWe are an equal opportunity employer.

-

5 Tips for Acing Your Virtual Interview

5 Tips for Acing Your Virtual InterviewDalena Nguyen, a Talent Acquisition Advisor, shares her top tips for making a great first impression when interviewing by phone or online.

-

'Never stop learning'

'Never stop learning'Discover how our digital learning resources helped Boeing India teammate Antara upskill.

-

Meet Abbey Carlson: Former Intern Turned Space and Launch Engineer

Meet Abbey Carlson: Former Intern Turned Space and Launch EngineerAbbey Carlson, a former Boeing intern, shares her two major milestones: graduating from college and accepting her first job with Boeing.

-

Meet Francis: Inventor Strives to Make Space Safer

Meet Francis: Inventor Strives to Make Space SaferA Senior Composite Engineer at Boeing’s Satellite Development Center, Francis, says each patent represents a step toward achieving her childhood goal to make space safer.

-

‘Engineering reaches every industry; it’s part of everyday life’

‘Engineering reaches every industry; it’s part of everyday life’Meet Hana McKee, an engineer whose curiosity inspires her to innovate the next generation of rotorcraft.

-

Jae’s Early Fascination With Flight Led to a Role at Boeing

Jae’s Early Fascination With Flight Led to a Role at BoeingMeet Jae, a systems engineer on the world’s leading airborne early warning and control aircraft, Boeing’s E-7A Wedgetail.

-

A Veteran's Secret Weapon

A Veteran's Secret WeaponWhat Marcie Purser, program management specialist, brings to the table is highly valued at Boeing: lasting connection.

-

On a Mission to Lead

On a Mission to LeadLearn how one of our development programs – a partnership with MIT – is helping an engineer get on a path to executive leadership.

-

'The possibilities are endless'

'The possibilities are endless'From space to defense, senior software and project engineer, Kimberly Sledge, inspires the next generation of Black women in STEM.

-

Meet OB, Starliner Spacecraft Technician

Meet OB, Starliner Spacecraft TechnicianFrom making repairs on aircraft to building spacecraft, Oborsouis "OB" has had his hands in a little bit of everything.

-

Aim High: Meet Kristine, Space Launch Systems Engineer

Aim High: Meet Kristine, Space Launch Systems EngineerKristine Ramos, design engineer, goes above and beyond to advocate for human spaceflight.

-

‘I’m a lifelong learner’

‘I’m a lifelong learner’Meet Nixon, an engineer who uses our tuition assistance to stay on the cutting edge of emerging technology.

-

‘I don’t just translate — I bridge gaps’

‘I don’t just translate — I bridge gaps’Meet Dama, an engineer and manager who strengthens our company by being a cultural and technical integrator.

-

‘I’ve challenged myself to grow’

‘I’ve challenged myself to grow’Read how Kaomi Hashimoto has grown her career across continents, while supporting our next generation of leaders.

-

'Helping people reach their potential inspires me'

'Helping people reach their potential inspires me'Meet Wilton, a Quality manager for the Space Launch System program who helps create a culture where everyone can speak up.

-

‘I encourage others to take this opportunity!’

‘I encourage others to take this opportunity!’From aircraft assembler to avionics engineer, Vadym Vasylyshyn grew his career with our tuition assistance program.

-

'Lean into discomfort': Career Advice From a Chief Engineer

'Lean into discomfort': Career Advice From a Chief EngineerPete Kunz, Phantom Works chief engineer, describes opportunities that have shaped his career and shares tips for success.

-

'It may not be easy, but it will pay off': Meet Rayni Sivley

'It may not be easy, but it will pay off': Meet Rayni SivleyAs project manager for Ground-based Midcourse Defense, Rayni isn't bothered by roadblocks. Read her advice for career growth.

-

Love at First Flight

Love at First FlightAn operations manager and an analyst for the V-22 tiltrotor thrive on teamwork in the factory and at home.

-

Cybersecurity Careers at Boeing

Cybersecurity Careers at BoeingBoeing is more than airplanes. More than satellites. More than cutting-edge cyber solutions. We work together with advanced technology on projects for the defense and intelligence communities. Join our Cybersecurity team.

-

Electronic and Electrical Engineering Careers at Boeing

Electronic and Electrical Engineering Careers at BoeingElectrical engineers work closely with our customers to develop electronic and electrical systems for Boeing aircraft, and world-class autonomous robotic systems for space, terrestrial, and underwater hardware. Learn more about the team.

-

Finance Careers at Boeing

Finance Careers at BoeingOur finance professionals play a key role in guiding critical business decisions and cutting-edge solutions for the world’s leading aerospace company. Learn more.

-

Flight Engineering Careers at Boeing

Flight Engineering Careers at BoeingFlight engineers are essential to the development, safety and success of our products and solutions. Learn more about the team.

-

Information Technology Internships at Boeing

Information Technology Internships at BoeingLearn how you can get access to cutting-edge technology and grow your skills through our Information Technology & Data Analytics Intern Program.

-

Electrical Engineering Internships

Electrical Engineering InternshipsA chance to start your career designing and building our next generation of products.

-

Human Resources Careers at Boeing

Human Resources Careers at BoeingBoeing HR professionals support our employees as they manage their career path, develop their teams and chart the course for career development. Learn how you can join the team.

-

Industrial Engineering Careers at Boeing

Industrial Engineering Careers at BoeingDiscover how you can make a difference at Boeing as an industrial engineer. Become part of a team that drives innovation across diverse technologies worldwide.

-

Test and Evaluation Engineering Careers at Boeing

Test and Evaluation Engineering Careers at BoeingAs a Test and Evaluation Engineer at Boeing, you'll ensure that our next-generation commercial and defense products and systems meet the highest standards. Join us as we continue to push the boundaries of aerospace.

-

Software Engineering Careers at Boeing

Software Engineering Careers at BoeingAs a software engineer at Boeing your code will power products that defy gravity and fly faster than the speed of sound.

-

Supply Chain Management Careers at Boeing

Supply Chain Management Careers at BoeingWith a career in supplier management at Boeing, you can help solve business challenges that are redefining an entire industry.

-

Systems Engineering Careers at Boeing

Systems Engineering Careers at BoeingAs a Systems Engineer at Boeing, you can help drive the overall design of innovative and high-quality products and solutions.

-

Business Operations Internships

Business Operations InternshipsIn our Business Intern Program, you can be part of a team that is helping shape the future of aerospace.

-

-

Human Resources Internships

Human Resources InternshipsIn our Business Intern Program, you can be part of a team that is helping shape the future of aerospace.

-

Supply Chain Internships

Supply Chain InternshipsIn our Supply Chain Intern Program, you can be part of a team that is helping shape the future of aerospace.

-

Data Science and Analytics Careers at Boeing

Data Science and Analytics Careers at BoeingData doesn’t work in silos — it needs to breathe and interact with other information in order to tell the whole story, not just parts of it. At Boeing, we’re working across our enterprise to let data and information drive our collective decision-making. Join our Data Science and Analytics team today.

-

Information Technology Careers at Boeing

Information Technology Careers at BoeingAs part of our Information Technology and Data Analytics team, you’ll support one of the largest corporate IT portfolios anywhere. Join us and help build the future.

-

Materials, Process and Physics Engineering Careers at Boeing

Materials, Process and Physics Engineering Careers at BoeingCome build the future with Boeing and develop the next generation of aircraft, space and underwater vehicles and revolutionary approaches to manufacturing.

-

Mechanical and Structural Engineering Careers at Boeing

Mechanical and Structural Engineering Careers at BoeingMechanical and structural engineers at Boeing develop and apply innovative technologies that shape the future. Learn more.

-

Product Security Engineering Careers at Boeing

Product Security Engineering Careers at BoeingDiscover how you can make a difference at Boeing as a product security engineer. Become part of a team that drives innovation across diverse technologies worldwide.

-

Production Engineering Careers at Boeing

Production Engineering Careers at BoeingAt Boeing, our production engineers use their skills to build the future of advanced manufacturing. Learn more.

-

Manufacturing Careers

Manufacturing CareersEvery day around the globe, Boeing manufacturing employees build the future of aerospace. Join our team. Your future is waiting.

-

Specialty Engineering Internships

Specialty Engineering InternshipsA chance to start your career designing and building our next generation of products.

-

Software Engineering Internships

Software Engineering InternshipsA chance to start your career designing and building our next generation of products.

-

Systems Engineering Internships

Systems Engineering InternshipsA chance to start your career designing and building our next generation of products.

-

Test & Evaluation Engineering Internships

Test & Evaluation Engineering InternshipsA chance to start your career designing and building our next generation of products.

-

-

-

Global Real Estate and Facilities Internships

Global Real Estate and Facilities InternshipsA chance to start your career designing and building our next generation of products.

-

Finance Internships

Finance InternshipsIn our Finance Intern Program, you can be part of a team that is helping shape the future of aerospace.

-

Flight Engineering Internships

Flight Engineering InternshipsA chance to start your career designing and building our next generation of products.

-

Industrial Engineering Internships

Industrial Engineering InternshipsA chance to start your career designing and building our next generation of products.

-

Materials, Process & Physics Engineering Internships

Materials, Process & Physics Engineering InternshipsA chance to start your career designing and building our next generation of products.

-

Mechanical & Structural Internships

Mechanical & Structural InternshipsA chance to start your career designing and building our next generation of products.

-

Facilities and Asset Management Engineering Internships

Facilities and Asset Management Engineering InternshipsA chance to start your career designing and building our next generation of products.

-

Boeing in Ukraine

Boeing in UkraineOur teams in Ukraine provide engineering expertise, consultation services, research and technical assistance for our platforms and aircraft that fly worldwide.

-

The sky’s the limit

The sky’s the limitMeet Ronak, a Boeing India teammate who’s used our tuition assistance to grow his career, studying online and abroad.

-

Boeing in Australia

Boeing in AustraliaJoin a team of more than 4,300 people providing leading-edge aviation services for our defense and commercial customers.

-

Military Spouse Career Accelerator Pilot Program

Military Spouse Career Accelerator Pilot ProgramOur 12-week paid fellowship connects individuals with training, networking opportunities and hands-on experience.

-

-

Excellence with Caring' is Key: Meet Dr. Nathan Brooks

Excellence with Caring' is Key: Meet Dr. Nathan BrooksBoeing's first Black Senior Technical Fellow grew from humble beginnings to executive leader and mentor.

-

AI creator changes how autonomous systems work

AI creator changes how autonomous systems work‘It’s about technology and innovation that will transform aerospace as we know it.’

-

-

-

Explore careers with Boeing Phantom Works

Explore careers with Boeing Phantom WorksDiscover a career with Phantom Works, Boeing’s advanced research and development division, and shape the future of aerospace. Apply today for engineering, cybersecurity, data intelligence jobs and more.

-

-

UK Apprenticeship

UK ApprenticeshipOur three-year apprenticeships offer diverse experiences and prepare you to work on our aircraft.

-

Jenna’s career path has been anything but traditional.

Jenna’s career path has been anything but traditional.Veteran, military spouse and engineer, Jenna believes there are many paths to success.

-

-

-

“When you ask veterans for help, you get it.”

“When you ask veterans for help, you get it.”Joshua, a veteran of the U.S. Air Force, once helped repair our aircraft. Now he flies in them.

-

-

-

Product Support Engineering Internships

Product Support Engineering InternshipsA chance to start your career designing and building our next generation of products.

-

Product Security Engineering Internships

Product Security Engineering InternshipsA chance to start your career designing and building our next generation of products.

-

Production Engineering Internships

Production Engineering InternshipsA chance to start your career designing and building our next generation of products.

-

Safety & Airworthiness Engineering Internships

Safety & Airworthiness Engineering InternshipsA chance to start your career designing and building our next generation of products.

-

Tristan Crumley | Design Engineer Intern

Tristan Crumley | Design Engineer InternTristan helps his team create experimental hardware designs for propulsion applications.

-

Adrian Sosa | Structures Design Engineer Intern

Adrian Sosa | Structures Design Engineer InternAdrian supports the efficiency and reliability of 777X wing structures through innovative design solutions.

-

Mya Beathley | Engineering Intern

Mya Beathley | Engineering InternLearn how Mya contributes to safety and certification standards for Boeing Defense, Space & Security.

-

Eva Strang | Strategy Analyst Intern

Eva Strang | Strategy Analyst InternThrough Aerospace Xelerated, Eva supports aerospace startups, fostering innovation and industry advancement.

-

Elisa Rwagasana Ishimwe | Information Technology and Data Analytics Intern

Elisa Rwagasana Ishimwe | Information Technology and Data Analytics InternElisa’s passion for aviation motivates her to enhance internal tools that improve collaboration.

-

Niyathi Gorantla | Sustainability Intern

Niyathi Gorantla | Sustainability InternMeet Niyathi, who manages projects for our Sustainable Aerospace Together Forum.

-

-

Atira Sarat | Sustainability Innovation Research Intern

Atira Sarat | Sustainability Innovation Research InternAs a Research Intern, Atira is working on real-world projects and helping to shape the future of aerospace.

-

Adrian Loekman | Airplane Maintenance Engineering Intern

Adrian Loekman | Airplane Maintenance Engineering InternFrom day one, Adrian felt welcomed and part of a collaborative team.

-

Đoàn Sĩ Anh | Retrofit Engineering Intern

Đoàn Sĩ Anh | Retrofit Engineering InternFrom Vietnam to the United States, Doan learned about our company from engineers around the world.

-

-

A passion for propulsion helps fuel the future of flight

A passion for propulsion helps fuel the future of flightDominic and his team are at the forefront of studying alternative energy sources and future flight concepts.

-

Security clearance levels for aerospace & defense jobs explained

Security clearance levels for aerospace & defense jobs explainedLearn about the different security clearance levels required for aerospace and defense jobs. Learn how to transfer active clearances to a job at Boeing

-

High-demand jobs for people with security clearances

High-demand jobs for people with security clearancesLearn how having a security clearance can open new career and growth opportunities in the aerospace and defense industry.

-

FAQs on applying for jobs that require a security clearance.

FAQs on applying for jobs that require a security clearance.Find answers to common questions about applying for aerospace and defense jobs that require a security clearance.

-

Career development for military spouses at Boeing

Career development for military spouses at BoeingExplore job opportunities for military spouses at Boeing, including for jobs that require security clearance.

-

Get your degree on us

Get your degree on usOur tuition assistance program pays your institution directly so you don't have to. Learn more about how we fund courses, certificates and degrees.

-

-

From excavating bones to building Boeing systems

From excavating bones to building Boeing systemsTori started her career digging up ancient bones as a budding archeologist. Today, she’s a systems engineer for our E-7A Wedgetail program in Adelaide, South Australia.

-

Boeing Pre-Employment Training Program

Boeing Pre-Employment Training ProgramThe Boeing Pre-Employment Training Program (BPET) allows students from pre-certified academic manufacturing programs to skip the interview process when applying for specific manufacturing jobs at Boeing.

-

Boeing Pre-Employment Training Program

Boeing Pre-Employment Training ProgramThe Boeing Pre-Employment Training Program (BPET) in South Carolina allows students from pre-certified academic manufacturing programs to skip the interview process when applying for specific manufacturing jobs at Boeing.

-

Translate your military experience

Translate your military experienceVisit Oplign and match your unique skills and experience to our open roles.

-

-

-

-

-

-

-

Entry-Level Careers

Entry-Level CareersWork on projects with a scope few companies can match in an entry-level role — where many of our senior leaders started their careers.

-

-

Apply to Supply Chain Management Jobs

- Working student / Werkstudent - Flight Deck for Boeing Commercial Airplanes (m/f/d) Neu-Isenburg, Germany 02/19/2026

- Supply Base Management Specialist (Manager) Long Beach, California, United States 02/19/2026

- C-17 International Training Centre - Business Support (12 months FTC) Farnborough, United Kingdom 02/19/2026

- Experienced Used Serviceable Materials Supply Chain Specialist Dallas, Texas, United States 02/19/2026

Jobs for You:

No recently viewed jobs.

View all of our available opportunitiesNo saved jobs.

View all of our available opportunitiesConnect with us

Join our Talent Community

Get updates about Boeing job opportunities, events and career information.

Sign up for our Talent CommunityVeteran Talent Community

Transition to a career in engineering, product support, IT, manufacturing or other areas.

Sign up for our Veteran Talent Community